Abstract

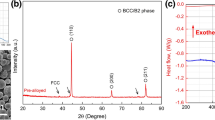

A bulk NbCr2 Laves phase matrix composite toughened with ductile Cr phase has been fabricated by spark plasma sintering (SPS) using pre-alloyed NbCr2 and Cr powders. The sintering behaviour and phase morphological evolution of the sintered alloy were investigated. The results show that a series of microstructure evolutions along the sintering temperature occurred: elongated Cr phase with uniform dispersion of fine NbCr2 and Cr phase → coarse Cr phase with matured fine NbCr2 and Cr → coarse Cr and Nb phases with lamellar eutectics. The microstructural evolution and phase transformation along the sintering temperature are analyzed by considering the inhomogenous temperature distribution and the accelerated atomic diffusion due to the pulsed electric current applied during SPS. The room temperature fracture toughness of the sintered samples is expected to be markedly improved due to the absence of lamellar or the occurrence of ductile Cr and Nb phases.

Similar content being viewed by others

References

N.Y. Yurchenko, N.D. Stepanov, D.G. Shaysultanov, M.A. Tikhonovsky, and G.A. Salishchev: Effect of Al content on structure and mechanical properties of the AlxCrNbTiVZr (x = 0; 0.25; 0.5; 1) high-entropy alloys. Mater. Charact. 121, 125 (2016).

N. Takata, H. Ghassemi-Armaki, M. Takeyama, and S. Kumar: Nanoindentation study on solid solution softening of Fe-rich Fe2Nb Laves phase by Ni in Fe–Nb–Ni ternary alloys. Intermetallics 70, 7 (2016).

C. Ghosh, J. Basu, D. Ramachandran, and E. Mohandas: Alloy design and microstructural evolution in V–Ti–Cr alloys. Mater. Charact. 106, 292 (2015).

W. Luo, C. Kirchlechner, X. Fang, S. Brinckmann, G. Dehm, and F. Stein: Influence of composition and crystal structure on the fracture toughness of NbCo2 Laves phase studied by micro-cantilever bending tests. Mater. Des. 145, 116 (2018).

S.Q. Lu, H.Z. Zheng, and M.W. Fu: The fracture toughness of hot-pressed NbCr2 alloys doped by rare earth yttrium. Scr. Mater. 61, 205 (2009).

S. Lu, H. Zheng, L. Deng, and J. Yao: Effect of silicon on the fracture toughness and oxidation behavior of hot pressed NbCr2 alloys. Mater. Des. 51, 432 (2013).

J. Aufrecht, A. Leineweber, A. Senyshyn, and E.J. Mittemeijer: The absence of a stable hexagonal Laves phase modification NbCr2 in the Nb–Cr system. Scr. Mater. 62, 227 (2010).

T. Ohta, Y. Nakagawa, Y. Kaneno, H. Inoue, T. Takasugi, and W-Y. Kim: Microstructures and mechanical properties of NbCr2 and ZrCr2 Laves phase alloys prepared by powder metallurgy. J. Mater. Sci. 38, 657 (2003).

Q. Long, J. Wang, Y. Du, D. Holec, X. Nie, and Z. Jin: Predicting an alloying strategy for improving fracture toughness of C15 NbCr2 Laves phase: A first-principles study. Comput. Mater. Sci. 123, 59 (2016).

K. Li, R. Hao, C. Di, and D. Gong: Microstructure and mechanical properties of Laves phase NbCr2-based composites toughened with Cr phase fabricated by spark plasma sintering. J. Mater. Res. 31, 2214 (2016).

C.T. Liu, J.H. Zhu, M.P. Brady, C.G. McKamey, and L.M. Pike: Physical metallurgy and mechanical properties of transition-metal Laves phase alloys. Intermetallics 8, 1119 (2000).

Y.L. Xue, S.M. Li, H. Zhong, and H.Z. Fu: Characterization of fracture toughness and toughening mechanisms in Laves phase Cr2Nb based alloys. Mater. Sci. Eng., A 638, 340 (2015).

K. Li, S. Li, Y. Xue, and H. Fu: Microstructure characterization and mechanical properties of a Laves-phase alloy based on Cr2Nb. Int. J. Refract. Met. Hard Mater. 36, 154 (2013).

M. Takeyama and C.T. Liu: Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb. Mater. Sci. Eng., A 132, 61 (1991).

Y. Xue, S. Li, H. Zhong, K. Li, and H. Fu: Phase selections and mechanical properties of ternary Cr–Nb–Ti alloys under rapid solidification. J. Alloys Compd. 684, 403 (2016).

X.W. Nie, S.Q. Lu, K.L. Wang, T.C. Chen, and C.L. Niu: Fabrication and toughening of NbCr2 matrix composites alloyed with Ni obtained by powder metallurgy. Mater. Sci. Eng., A 502, 85 (2009).

P. Shayesteh, S. Mirdamadi, and H. Razavi: Study the effect of mechanical alloying parameters on synthesis of Cr2Nb–Al2O3 nanocomposite. Mater. Res. Bull. 49, 50 (2014).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu: Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 56, 24 (2015).

F.C. Wang, Z.H. Zhang, Y.J. Sun, Y. Liu, Z.Y. Hu, H. Wang, A.V. Korznikov, E. Korznikova, Z.F. Liu, and S. Osamu: Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon 95, 396 (2015).

Z.H. Zhang, F.C. Wang, L. Wang, and S.K. Li: Ultrafine-grained copper prepared by spark plasma sintering process. Mater. Sci. Eng. A476, 201 (2008).

B. Han, C. Zhao, Z.X. Zhu, X. Chen, Y. Han, D. Hu, M.H. Zhang, H.C. Thong, and K. Wang: Temperature-insensitive piezoelectric performance in Pb(Zr0.52Ti0.42Sn0.02Nb0.04)O3 ceramics prepared by spark plasma sintering. ACS Appl. Mater. Interfaces 9, 34078 (2017).

B. Srinivasarao, K. Oh-ishi, T. Ohkubo, and K. Hono: Bimodally grained high-strength Fe fabricated by mechanical alloying and spark plasma sintering. Acta Mater. 57, 3277 (2009).

O. El-Atwani, D.V. Quach, M. Efe, P.R. Cantwell, B. Heim, B. Schultz, E.A. Stach, J.R. Groza, and J.P. Allain: Multimodal grain size distribution and high hardness in fine grained tungsten fabricated by spark plasma sintering. Mater. Sci. Eng., A 528, 5670 (2011).

K.W. Li, S.M. Li, K. Gao, and D.Q. Gong: Synthesis and characterization of NbCr2 Laves phase produced by spark plasma sintering. J. Mater. Res. 31, 380 (2016).

C. Suryanarayana: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1 (2001).

A.R. Yavari: Reordering kinetics and magnetic properties of mechanically disordered nanocrystalline Ll2-type Ni3Al + Fe alloys. Acta Metall. Mater. 41, 1391 (1993).

F. Hadef: Synthesis and disordering of B2 TM-Al (TM = Fe, Ni, Co) intermetallic alloys by high energy ball milling: A review. Powder Technol. 311, 556 (2017).

F. Stein, C. He, and I. Wossack: The liquidus surface of the Cr–Al–Nb system and re-investigation of the Cr–Nb and Al–Cr phase diagrams. J. Alloys Compd. 598, 253 (2014).

K.W. Li, S.M. Li, H. Zhong, Y.L. Xue, and H.Z. Fu: Solidification behavior and microstructural evolution of the Cr–Nb eutectic alloy. Cryst. Res. Technol. 48, 430 (2013).

B.P. Bewlay, J.A. Sutliff, M.R. Jackson, and H.A. Lipsitt: Microstructural and crystallographic relationships in directionally solidified Nb–Cr2Nb and Cr–Cr2Nb eutectics. Acta Metall. Mater. 42, 2869 (1994).

B.P. Bewlay, H.A. Lipsitt, M.R. Jackson, W.J. Reeder, and J.A. Sutliff: Solidification processing of high temperature intermetallic eutectic-based alloys. Mater. Sci. Eng., A 192–193, 534 (1995).

Z.A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi: The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 41, 763 (2006).

P. Pei, X.P. Song, J. Liu, M. Zhao, and G.L. Chen: Improving hydrogen storage properties of Laves phase related BCC solid solution alloy by SPS preparation method. Int. J. Hydrogen Energy 34, 8597 (2009).

K.S. Kumar, L. Pang, J.A. Horton, and C.T. Liu: Structure and composition of Laves phases in binary Cr–Nb, Cr–Zr and ternary Cr–(Nb, Zr) alloys. Intermetallics 11, 677 (2003).

K.S. Kumar, L. Pang, C.T. Liu, J. Horton, and E.A. Kenik: Structural stability of the Laves phase Cr2Ta in a two-phase Cr–Cr2Ta alloy. Acta Mater. 48, 911 (2000).

X. Song, X. Liu, and J. Zhang: Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J. Am. Ceram. Soc. 89, 494 (2006).

K.N. Tu, C.C. Yeh, C.Y. Liu, and C. Chen: Effect of current crowding on vacancy diffusion and void formation in electromigration. Appl. Phys. Lett. 76, 988 (2000).

Y. Liu, J. Fan, H. Zhang, W. Jin, H. Dong, and B. Xu: Recrystallization and microstructure evolution of the rolled Mg–3Al–1Zn alloy strips under electropulsing treatment. J. Alloys Compd. 622, 229 (2015).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China under Grant No. 51604190 and the State Key Laboratory of Solidification Processing in NWPU under Grant No. SKLSP201824.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, K., Gao, F. & Wang, L. Microstructure and phase evolution in spark plasma sintering of the NbCr2 Laves phase matrix composite toughened with ductile Cr phase. Journal of Materials Research 33, 4329–4339 (2018). https://doi.org/10.1557/jmr.2018.371

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.371