Abstract

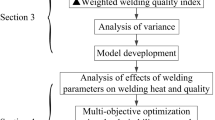

The present study aims to solve multi-response optimization problem in small scale resistance spot welding of 0.4-mm-thick TC2 titanium alloy sheets. Welding parameters of electrode force, welding current and welding time were arranged by the central composite experimental design. Principal component analysis was conducted first on quality indicators of nugget diameter, failure load, failure displacement and failure energy. Different weighted principal components selection strategies were performed to calculate the composite weld quality indexes. Multiple stepwise regression analysis was applied to develop the mathematical function for weighted principal components prediction. Welding parameters effects and sensitivity analysis on the composite weld quality index were discussed. Welding current was found the most significant factor affecting weld quality. Optimum welding parameters determined by genetic algorithm were validated through experiments. The first principal component was supposed as the most effective and simplest quality index. Weld quality was considerably improved based on the proposed model.

Similar content being viewed by others

References

Steinmeier D (1998) Downsizing in the world of resistance welding—General comparisons between large-, small- and micro-scale resistance spot welding. Weld J 77(7):39–47

Dong S, Kelkar G, Zhou Y (2002) Electrode sticking during micro-resistance welding of thin metal sheets. IEEE Trans Electron Packag Manuf 25(4):355–361. doi:10.1109/TEPM.2002.807732

Li W, Suo J, Ma T, Feng Y, Kim K (2014) Abnormal microstructure in the weld zone of linear friction welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy joint and its influence on joint properties. Mater Sci Eng A-Struct Mater Prop Microstruct Process 599:38–45. doi:10.1016/j.msea.2014.01.071

Kaya Y, Kahraman N (2012) The effects of electrode force, welding current and welding time on the resistance spot weldability of pure titanium. Int J Adv Manuf Technol 60(1-4):127–134. doi:10.1007/s00170-011-3604-z

Chang B, Li M, Zhou Y (2001) Comparative study of small scale and ‘large scale’ resistance spot welding. Sci Technol Weld Join 6(5):273–280. doi:10.1179/136217101101538875

Xu J, Zhai T (2008) The small-scale resistance spot welding of refractory alloy 50Mo-50Re thin sheet. JOM 60(7):80–83. doi:10.1007/s11837-008-0096-x

Taguchi G (1990) Introduction to quality engineering. Asian Productivity Organization, Tokyo

Gauri SK, Chakraborty S (2009) Multi-response optimisation of WEDM process using principal component analysis. Int J Adv Manuf Technol 41:741–748. doi:10.1007/s00170-008-1529-y

Gauri SK, Pal S (2014) The principal component analysis (PCA)-based approaches for multi-response optimization: some areas of concerns. Int J Adv Manuf Technol 70:1875–1887. doi:10.1007/s00170-013-5389-8

Su CT, Tong LI (1997) Multi-response robust design by principal component analysis. Total Qual Manage 8(6):409–416. doi:10.1080/0954412979415

Kaiser HF (1960) The application of electronic computers to factor analysis. Educ Psychol Meas 20:141–151

Antony J (2000) Multi-response optimization in industrial experiments using Taguchi’s quality loss function and principal component analysis. Qual Reliab Eng Int 16(1):3–8. doi:10.1002/(SICI)1099-1638(200001/02)16:1%3C3::AID-QRE276%3E3.0.CO;2-W

Fung C, Kang P (2005) Multi-response optimization in friction properties of PBT composites using Taguchi method and principle component analysis. J Mater Process Technol 170(3):602–610. doi:10.1016/j.jmatprotec.2005.06.040

Liao H (2006) Multi-response optimization using weighted principal component. Int J Adv Manuf Technol 27(7-8):720–725. doi:10.1007/s00170-004-2248-7

Gauri SK, Chakraborty S (2009) Optimisation of multiple responses for WEDM processes using weighted principal components. Int J Adv Manuf Technol 40:1102–1110. doi:10.1007/s00170-008-1429-1

Datta S, Nandi G, Bandyopadhyay A, Pal PK (2009) Application of PCA-based hybrid Taguchi method for correlated multicriteria optimization of submerged arc weld: a case study. Int J Adv Manuf Technol 45(3-4):276–286. doi:10.1007/s00170-009-1976-0

Kim T, Park H, Rhee S (2005) Optimization of welding parameters for resistance spot welding of TRIP steel with response surface methodology. Int J Prod Res 43(21):4643–4657. doi:10.1080/00207540500137365

Kumar A, Kumar V, Kumar J (2013) Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int J Adv Manuf Technol 68:2645–2668. doi:10.1007/s00170-013-4861-9

Pal S, Gauri SK (2010) Multi-response optimization using multiple regression-based weighted signal-to-noise ratio (MRWSN). Qual Eng 22(4):336–350. doi:10.1080/08982112.2010.495368

Vijian P, Arunachalam VP (2007) Modelling and multi objective optimization of LM24 aluminium alloy squeeze cast process parameters using genetic algorithm. J Mater Process Technol 186(1-3):82–86. doi:10.1016/j.jmatprotec.2006.12.019

Boopathi S, Sivakumar K (2013) Experimental investigation and parameter optimization of near-dry wire-cut electrical discharge machining using multi-objective evolutionary algorithm. Int J Adv Manuf Technol 67:2639–2655. doi:10.1007/s00170-012-4680-4

Pearson K (1901) On lines and planes of closest fit to systems of points in space. Philos Mag Series 2(11):559–572

Hotelling H (1933) Analysis of a complex of statistical variables into principal components. J Educ Psychol 24(6):417– 441

Holland J (1975) Adaptation in natural and artificial system. University of Michigan Press, Ann Arbor

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, X., Wang, Y. & Zhao, D. Multi-response optimization in small scale resistance spot welding of titanium alloy by principal component analysis and genetic algorithm. Int J Adv Manuf Technol 83, 545–559 (2016). https://doi.org/10.1007/s00170-015-7545-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7545-9