Abstract

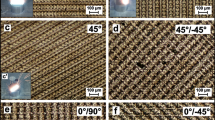

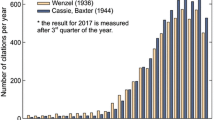

Three different microstructures with line pattern, grid pattern, and spot pattern were fabricated on titanium surfaces by nanosecond laser. Scanning electron microscopy (SEM), contact angle measurement, surface roughness gage, and X-ray photoelectron spectroscopy (XPS) analyses were used to characterize and measure the surface morphology, contact angle, surface roughness, and chemical composition of titanium after laser processing. The results indicate that the contact angle of titanium surface is 77.8° immediately after laser processing, which shows hydrophilicity, and the contact angle presents a rising tendency with time in general. At steady state, the maximum contact angles for line pattern, grid pattern, and spot pattern increased to 157.2°, 153°, and 132.5°, respectively. It can be found that the surface wettability has changed from hydrophilicity to hydrophobicity and even to superhydrophobicity. The influence of surface morphology on the surface wettability effects immediately after laser treatment and does not change with time, while the effect of surface chemical composition on the surface wettability will continue from the beginning of laser processing to the stabilization of surface chemical composition. Finally, it can be deduced that the accumulation of carbon on the surface is probably the critical factor to improve the surface hydrophobicity. Therefore, it is concluded that laser-induced modification of surface wettability correlates with surface morphology and surface chemical composition.

Similar content being viewed by others

References

Marmur A (2006) Soft contact: measurement and interpretation of contact angles. Soft Matter 2(1):12–17. doi:10.1039/b514811c

Lu Y, Guo P, Pei PC, Ehmann KF (2015) Experimental studies of wettability control on cylindrical surfaces by elliptical vibration texturing. Int J Adv Manuf Technol 76:1807–1817. doi:10.1007/s00170-014-6384-4

Bhushan B, Jung YC, Koch K (2009) Self-cleaning efficiency of artificial superhydrophobic surfaces. Langmuir 25(5):3240–3248. doi:10.1021/la803860d

Kulinich SA, Farhadi S, Nose K, Du XW (2011) Superhydrophobic surfaces: are they really ice-repellent. Langmuir 27(1):25–29. doi:10.1021/la104277q

Ishizak T, Hieda J, Saito N, Saito N, Takai O (2010) Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition. Electrochim Acta 55(23):7094–7101. doi:10.1016/j.electacta.2010.06.064

Carlborg CF, Van Der Wijingaart W (2011) Sustained superhydrophobic friction reduction at high liquid pressures and large flows. Langmuir 27(1):487–493. doi:10.1021/la103624d

Bormashenko E, Pogreb R, Bormashenko Y, Musin A, Stein T (2008) New investigations on ferrofluidics: ferrofluidic marbles and magnetic-field-driven drops on superhydrophobic surfaces. Langmuir 24(21):12119–12122. doi:10.1021/la802355y

Balu B, Berry AD, Hess DW, Breedveld V (2009) Patterning of superhydrophobic paper to control the mobility of micro-liter drops for two-dimensional lab-on-paper applications. Lab Chip 9(21):3066–3075. doi:10.1039/B909868B

Onda T, Shibuichi S, Satoh N, Tsujii K (1996) Super-water-repellent fractal surfaces. Langmuir 12(9):2125–2127. doi:10.1021/la950418o

Chen F, Zhang DS, Yang Q, Wang XH, Dai BJ, Li XM, Hao XQ, Ding YC, Si JH, Hou X (2011) Anisotropic wetting on microstrips surface fabricated by femtosecond laser. Langmuir 27(1):359–365. doi:10.1021/la103293j

Zhang DS, Chen F, Yang Q, Si JH, Hou X (2011) Mutual wetting transition between isotropic and anisotropic on directional structures fabricated by femotosecond laser. Soft Matter 7:8337–8342. doi:10.1039/C1SM05649B, Paper

Zhang JH, Li YF, Zhang XM, Yang B (2010) Colloidal self-assembly meets nanofabrication: from two-dimensional colloidal crystals to nanostructure arrays. Adv Mater 22:4249–4269. doi:10.1002/adma.201000755

Shchukin DG, Skorb E, Belova V, Möhwald H (2011) Ultrasonic cavitation at solid surfaces. Adv Mater 23:1922–1934. doi:10.1002/adma.201004494

Zahner D, Abagat J, Svec F, Fréchet JMJ, Levkin PA (2011) A facile approach to superhydrophilic–superhydrophobic patterns in porous polymer films. Adv Mater 23:3030–3034. doi:10.1002/adma.201101203

Cortese B, Amone SD, Manca M, Viola I, Cingolani R, Gigli G (2008) Superhydrophobicity due to the hierarchical scale roughness of PDMS surfaces. Langmuir 24:2712–2718. doi:10.1021/la702764x

Pernites RB, Ponnapati RR, Advincula RC (2011) Superhydrophobic–superoleophilic polythiophene films with tunable wetting and electrochromism. Adv Mater 23:3207–3213. doi:10.1002/adma.201100469

Mirhosseini N, Crouse PL, Schmidth MJJ, Li L, Garrod D (2007) Laser surface micro-texturing of Ti-6Al-4V substrates for improved cell integration. Appl Surf Sci 253(19):7783–7743. doi:10.1016/j.apsusc.2007.02.168

Luo BH, Shum PW, Zhou ZF, Li KY (2010) Preparation of hydrophobic surface on steel by patterning using laser ablation process. Surf Coat Technol 204(8):1180–1185. doi:10.1016/j.surfcoat.2009.10.043

Ma CH, Bai SX, Peng XD, Meng YG (2013) Improving hydrophobicity of laser textured SiC surface with micro-square convexes. Appl Surf Sci 266:51–56. doi:10.1016/j.apsusc.2012.11.068

Jagdheesh R (2014) Fabrication of a superhydrophobic Al2O3 surface using picosecond laser pulses. Langmuir 30(40):12067–12073. doi:10.1021/la5033527

Zhou K, Chen Y, Du ZW, Niu FL (2015) Surface integrity of titanium part by ultrasonic magnetic abrasive finishing. Int J Adv Manuf Technol 80:997–1005. doi:10.1007/s00170-015-7028-z

Rukosuyev MV, Lee J, Cho SJ, Lim G, Jun MBG (2014) One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation. Appl Surf Sci 313:411–417. doi:10.1016/j.apsusc.2014.05.224

Bizi-bandoki P, Valette S, Audouard E, Benayoun S (2013) Time dependency of the hydrophilicity and hydrophobicity of metallic alloys subjected to femtosecond laser irradiations. Appl Surf Sci 273:399–407. doi:10.1016/j.apsusc.2013.02.054

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Cj., Mei, Xs., Tian, Yl. et al. Modification of wettability property of titanium by laser texturing. Int J Adv Manuf Technol 87, 1663–1670 (2016). https://doi.org/10.1007/s00170-016-8601-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8601-9