Abstract

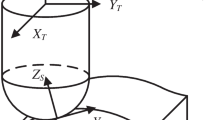

This paper presents a method for machining an annular groove on the inner wall of a steel tube by ball spinning. Based on spatial analytic geometry theory and assumptions about radial helical feed, the process utilizes a simplified expression of boundary curves of radial and tangential contact area between ball and workpiece. Through curve integration, the equations of radial and tangential contact areas for calculating ball-spinning force have been obtained. Based on results from calculation examples, this paper discusses the relationships between spinning depth, ball diameter, spinning feed, and ball-spinning force. The comparison of calculation results between the analytical model and the finite element method has been supplied, and the validity of the model has been certified.

Similar content being viewed by others

References

Maiß O, Denkena B, Grove T (2015) Hybrid machining of roller bearing inner rings by hard turning and deep rolling. J Mater Process Technol 230:211–216

Jiang S., Zhang Y., Zhao Y., Zhu X., Sun D., & Wang M. (2016) Investigation of interface compatibility during ball spinning of composite tube of copper and aluminum. Int J Adv Manuf Technol 1–8

Guo J, Qian D, Deng J (2015) Grain refinement limit during hot radial ring rolling of as-cast gcr15 steel. J Mater Process Technol 231:151–161

Huiping QI (2014) Research status and developing trends on the rolling forming process of ring parts. Chin J Mech Eng-en 50(14):75–80

Lin H (2008) 3d finite element method simulation and process design for cold rolling ball groove section ring. Chin J Mech Eng 44(10):201–205

MI Rotarescu, O Bologa, and N Turcu (1987) Cercetari experimentale privind unele marimi mecanice la deformarea volumica rotativa (Experimental Research on Some Mechanical Characteristics of the Bulk Rotary Forming Process), Proc. 1st. Conf. Def. Pl., Sibiu, pp.84–90

Lexian H, Dariani BM (2008) An analytical contact model for finite element analysis of tube spinning process. P I Mehc Eng B-J Eng 222(11):1375–1385

Wang D., Li M., & Cai Z. (2014) An investigation on roll adjusting radius in three-dimensional rolling process for three-dimensional surface parts. P I Mehc Eng B-J Eng 229(5)

MI Rotarescu, O Bologa and N Turcu (1987) Consideratii teoretice si stand experimental pentru cercetarea deformarii volumice rotative (Theoretical Remarks and Experimental Research Stand for Bulk Rotary Forming), Proc. 1st. Conf. Def. Pl., Sibiu, pp. 63–70

Mao-Sheng LI, Kang DC, Zhang SH, Yan YN (2004) Research on contacting pressure in ball-spinning. Mater Sci Tech-Lond 12(2):125–128

Kang DC, Mao-Sheng LI, Chen Y (2002) A study of force and power in ball spinning. Mater Sci Tech-Lond 10(2):179–182

Ma Zhenping, Zhang Tao (2011).The forming technology by ball spinning. Beijing Metallurgical Industry Press. (in Chinese)

Zhang GL, Zhang SH, Li B, Zhang HQ (2007) Analysis on folding defects of inner grooved copper tubes during ball spin forming. J Mater Process Technol 184(1–3):393–400

REN (2008) Analysis of mechanics in ball spinning of thin-walled tube. Chin J Mech Eng 21(1):25–30

JIANG SY, REN ZY (2004) Application of BPANN in spinning deformation of thin-walled tubular parts with longitudinal inner ribs. J Cent South Univ 11(1):27–30

Zhang SH, Li MS, Xu Y, Kang DC, Li CZ (2005) Introduction to a new cnc ball-spinning machine. J Mater Process Technol 170(1–2):112–114

Kuss M, Buchmayr B (2015) Analytical, numerical and experimental investigations of a ball spinning expansion process. J Mater Process Technol 224:213–221

Rotarescu MI (1995) A theoretical analysis of tube spinning using balls. J Mater Process Technol 54(1–4):224–229

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chunjiang, Z., Jie, X., Xiaodong, H. et al. The analytical model of ball-spinning force for processing an annular groove on the inner wall of a steel tube. Int J Adv Manuf Technol 91, 4183–4190 (2017). https://doi.org/10.1007/s00170-017-0077-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0077-8