Abstract

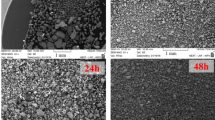

The aluminum-doped ZnO ceramic targets with 0.05 % silica doping (AZO:Si) were fabricated by slip casting and pressureless sintering using submicron ZnO and Al2O3 powders. The structure and properties of the AZO:Si targets were investigated at a temperature range of 1200–1450 °C. The structure, morphology, and electrical property of the AZO:Si targets were characterized by XRD, SEM and Hall effect. The results show that the silica can used as sintering aids to improve the density, and as donor to increase the conductivity of the AZO targets. The low sintering activity of submicron powders can be compensated by sintering aids and slip casting process. The AZO:Si targets exhibit higher density and conductivity than the pure AZO targets. Those targets fabricated by slip casting show homogeneous structure and large dimension.

Similar content being viewed by others

References

M.A. Santana-Aranda, A. Armenta-Estrada, C. Mendoza-Barrera, C.R. Michel, A. Chavez-Chavez, S. Jimenez-Sandoval, M. Melendez-Lira, J. Mater. Sci. Mater. Electron. 18, 611 (2007)

H.L. Hsu, C.B. Yang, C.H. Huang, C.Y. Hsu, J. Mater. Sci. Mater. Electron. 24, 13 (2013)

M. de La L Olvera, A. Maldonado, R. Asomoza, M. Melendez-Lira, J. Mater. Sci. Mater. Electron. 11, 1 (2000)

J.C. Chang, J.W. Guo, T.P. Hsieh, M.R. Yang, D.W. Chiou, H.T. Cheng, C.L. Yeh, C.C. Li, S.Y. Chu, Surf. Coat. Technol. 231, 573 (2013)

S.J. Tark, M.G. Kang, S. Park, J.H. Jang, J.C. Lee, W.M. Kim, J.S. Lee, D. Kim, Curr. Appl. Phys. 9, 1318 (2009)

B. He, J. Xu, H.Z. Xing, C.R. Wang, X.D. Zhang, Superlattices Microstruct. 64, 319 (2013)

Z. Deng, C. Huang, J. Huang, M. Wang, H. He, H. Wang, Y. Cao, J. Mater. Sci. Mater. Electron. 21, 1030 (2010)

Y.K. Moon, S.H. Kim, J.W. Park, J. Mater. Sci. Mater. Electron. 17, 973 (2006)

M. Schlott, M. Kutzner, B.L. Gehman, N. Reger, F.J. Stadermann, Digest of Technical Papers of SID International Symposium, 1 (1996)

T. Minami, J.I. Oda, J.I. Nomoto, T. Miyata, Thin Solid Films 519, 385 (2010)

K. Nakashima, Y. Kumahara, Vacuum 66, 221 (2002)

B.L. Gehman, S. Jonsson, T. Rudolph, M. Sherer, M. Weigert, R. Werner, Thin Solid Films 220, 333 (1992)

S.H. Cho, Y.M. Kang, J.R. Lee, B.K. Ryu, P.K. Song, J. Korean Phys. Soc. 54, 1315 (2009)

T. Omata, M. Kita, H. Okada, S. Otsuka-Yao-Matsuo, N. Ono, H. Ikawa, Thin Solid Films 503, 22 (2006)

K. Utsumi, O. Matsunaga, T. Takahata, Thin Solid Films 334, 30 (1998)

X. Wang, X. Bai, H. Duan, Z. Shi, J. Sun, S. Lu, S. Huang, Trans. Nonferrous Met. Soc. China 21, 1550 (2011)

T. Long, D.G. Zhu, L.H. Wang, Electron. Compon. Mater. 23, 31 (2004)

N. Neves, R. Barros, E. Antunes, J. Calado, E. Fortunato, R. Martins, I. Ferreira, J. Eur. Ceram. Soc. 32, 4381 (2012)

Y.H. Sun, W.H. Xiong, C.H. Li, L. Yuan, J. Am. Ceram. Soc. 92, 2168 (2009)

M.W. Wu, Ceram. Int. 38, 6229 (2012)

H.S. Huang, H.C. Tung, C.H. Chiu, I.T. Hong, R.Z. Chen, J.T. Chang, H.K. Lin, Thin Solid Films 518, 6071 (2010)

S. Tasaki, J. Tatami, H. Nakano, T. Wakihara, K. Komeya, T. Meguro, J. Ceram. Soc. Jpn. 118, 118 (2010)

J.W. Xu, Z.P. Yang, H. Wang, X.W. Zhang, Bull. Mater. Sci. 37, 895 (2014)

Y. Yang, P. Lan, M. Wang, T. Wei, R. Tan, W. Song, Nanoscale Res. Lett. 7, 481 (2012)

J. Liu, W. Zhang, D. Song, Q. Ma, L. Zhang, H. Zhang, X. Ma, H. Song, Mater. Sci. Semicond. Proc. 27, 1 (2014)

M. Powalla, B. Dimmler, Sol. Energy Mater. Sol. Cells 75, 27 (2003)

R. Papitha, M. Buchi Suresh, Y.S. Rao, B.P. Saha, D. Das, R. Johnson, Process. Appl. Ceram. 7, 159 (2013)

N. Rashidi, V.L. Kuznetsov, J.R. Dilworth, M. Pepper, P.J. Dobsonc, P.P. Edwards, J. Mater. Chem. C 1, 6960 (2013)

F. Chouikh, Y. Beggah, M.S. Aida, J. Mater. Sci. Mater. Electron. 22, 499 (2011)

G. Kim, J. Bang, Y. Kim, S.K. Rout, S.I. Woo, Appl. Phys. A 97, 821 (2009)

Y.H. Chou, J.L.H. Chau, W.L. Wang, C.S. Chen, S.H. Wang, C.C. Yang, Bull. Mater. Sci. 34, 477 (2011)

G. Tari, J.M.F. Ferreira, A.T. Fonseca, O. Lyckfeldt, J. Eur. Ceram. Soc. 18, 249 (1998)

S.M. Olhero, J.M.F. Ferreira, Ceram. Int. 28, 377 (2002)

W.S. Hong, L.C. Jonghe, X. Yang, M.N. Rahaman, J. Am. Ceram. Soc. 78, 3217 (1995)

K. Shirouzu, T. Ohkusa, M. Hotta, N. Enomoto, J. Hojo, J. Ceram. Soc. Jpn. 115, 254 (2007)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (21176051) and Guangxi Key Laboratory of Information Material (131024-Z).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Jw., Yang, Zp., Wang, H. et al. High density and low resistivity AZO:Si ceramic targets fabricated by slip casting and pressureless sintering using submicron powders. J Mater Sci: Mater Electron 26, 3819–3826 (2015). https://doi.org/10.1007/s10854-015-2908-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2908-4