Abstract

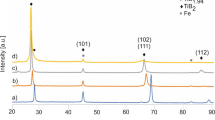

The high-entropy alloy (HEA) coatings have received considerable attentions owing to their unique structures and properties caused by the quick solidification. In this work, the CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb HEAs which show fully eutectic and hypereutectic microstructures in their casting samples were laser cladded on 304 stainless steel substrate with laser power of 1400, 1600, and 1800 W. Results show that the HEA coatings are composed of the FCC solid solution phase and the Fe2Nb-type Laves phase. The cladding zones of the CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb coatings show cellular dendritic crystals, while the bonding zones show directional columnar crystals. Compared to the 304 stainless steel substrate, the HEA coatings show better wear resistance because of the combination of the hard Fe2Nb-type Laves phase and the ductile FCC solid solution matrix. Moreover, the HEA coatings with power of 1600 W show the best wear resistance attributing to the maximum volume fraction of the hard Fe2Nb-type Laves phase.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299-303

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375-377, p 213-218

X.W. Qiu, Y.P. Zhang, L. He, and C.T. Liu, Microstructure and Corrosion Resistance of AlCrFeCuCo High Entropy Alloy, J. Alloys Compd., 2013, 549, p 195-199

Z. Tang, L. Huang, W. He, and P.K. Liaw, Alloying and Processing Effects on the Aqueous Corrosion Behavior of High-Entropy Alloys, Entropy, 2014, 16, p 895-911

C.F. Lee and T.T. Shun, Age Hardening of the Al0.5CoCrNiTi0.5 High-Entropy Alloy, Metall. Mater. Trans. A, 2014, 45, p 191-195

A.C. Yeh, Y.J. Chang, C.W. Tsai, Y.C. Wang, J.W. Yeh, and C.M. Kuo, On the Solidification and Phase Stability of a Co-Cr-Fe-Ni-Ti High-Entropy Alloy, Metall. Mater. Trans. A, 2014, 45, p 184-190

C.Y. Hsu, C.C. Juan, W.R. Wang, T.S. Sheu, J.W. Yeh, and S.K. Chen, On the Superior Hot Hardness and Softening Resistance of AlCoCrxFeMo0.5Ni High-Entropy Alloys, Mater. Sci. Eng. A, 2011, 528, p 3581-3588

W.P. Chen, Z.Q. Fu, S. Fang, H.Q. Xiao, and D.Z. Zhu, Alloying Behavior, Microstructure and Mechanical Properties in a FeNiCrCo0.3Al0.7 High Entropy Alloy, Mater. Des., 2013, 51, p 854-860

Y. Yu, W.M. Liu, T.B. Zhang, J.S. Li, J. Wang, H.C. Kou, and J. Li, Microstructure and Tribological Properties of AlCoCrFeNiTi0.5 High-Entropy Alloy in Hydrogen Peroxide Solution, Metall. Mater. Trans. A, 2014, 45, p 201-207

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59, p 6308-6317

B.R. Braeckman, F. Boydens, H. Hidalgo, P. Dutheil, M. Jullien, A.L. Thomann, and D. Depla, High Entropy Alloy Thin Films Deposited by Magnetron Sputtering of Powder Targets, Thin Solid Films, 2015, 580, p 71-76

S.Y. Chang, C.E. Li, Y.C. Huang, H.F. Hsu, J.W. Yeh, and S.J. Lin, Structural and Thermodynamic Factors of Suppressed Interdiffusion Kinetics in Multi-component High-entropy Materials, Sci. Rep., 2014, doi:10.1038/srep04162

M.H. Tsai, J.W. Yeh, and J.Y. Gan, Diffusion Barrier Properties of AlMoNbSiTaTiVZr High-Entropy Alloy Layer Between Copper and Silicon, Thin Solid Films, 2008, 516, p 5527-5530

Q.H. Li, T.M. Yue, Z.N. Guo, and X. Lin, Microstructure and Corrosion Properties of AlCoCrFeNi High Entropy Alloy Coatings Deposited on AISI, 1045 Steel by the Electrospark Process, Metall. Mater. Trans. A, 2013, 44, p 1767-1778

J.B. Cheng, X.B. Liang, Z.H. Wang, and B.S. Xu, Formation and Mechanical Properties of CoNiCuFeCr High-Entropy Alloys Coatings Prepared by Plasma Transferred Arc Cladding Process, Plasma Chem. Plasma Process., 2013, 33, p 979-992

S. Fang, W. Chen, and Z. Fu, Microstructure and Mechanical Properties of Twinned Al0.5CrFeNiCo0.3C0.2 High Entropy Alloy Processed by Mechanical Alloying and Spark Plasma Sintering, Mater. Des., 2014, 54, p 973-979

S. Zhang, C.L. Wu, and C.H. Zhang, Phase Evolution Characteristics of FeCoCrAlCuVxNi High Entropy Alloy Coatings by Laser High-Entropy Alloying, Mater. Lett., 2015, 141, p 7-9

S. Katakam, S.S. Joshi, S. Mridha, S. Mukherjee, and N.B. Dahotre, Laser Assisted High Entropy Alloy Coating on Aluminum: Microstructural Evolution, J. Appl. Phys., 2014, 116, p 104906

G. Meng, T.M. Yue, X. Lin, H. Yang, H. Xie, and X. Ding, Laser Surface Forming of AlCoCrCuFeNi Particle Reinforced AZ91D Matrix Composites, Opt. Laser Technol., 2015, 70, p 119-127

S. Zhang, C.L. Wu, J.Z. Yi, and C.H. Zhang, Synthesis and Characterization of FeCoCrAlCu High-Entropy Alloy Coating by Laser Surface Alloying, Surf. Coat. Technol., 2015, 262, p 64-69

H. Zhang, Y. Pan, and Y. He, Synthesis and Characterization of FeCoNiCrCu High-Entropy Alloy Coating by Laser Cladding, Mater. Des., 2011, 32, p 1910-1915

Y. Shon, S.S. Joshi, S. Katakam, R.S. Rajamure, and N.B. Dahotre, Laser Additive Synthesis of High Entropy Alloy Coating on Aluminum: Corrosion Behavior, Mater. Lett., 2015, 142, p 122-125

L. Jiang, Y.P. Lu, Y. Dong, T.M. Wang, Z.Q. Cao, and T.J. Li, Effects of Nb Addition on Structural Evolution and Properties of the CoFeNi2V0.5 High-Entropy Alloy, Appl. Phys. A, 2015, 119, p 291-297

Acknowledgments

This work was supported by the national natural science foundation of China Nos. (51574058, 51525401, U1332115, 51375070, and 51471044, respectively), the fundamental research funds for the central universities, key laboratory of basic research projects of Liaoning province department of education (LZ2014007), and the natural science foundation of Liaoning province (2014028013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, L., Wu, W., Cao, Z. et al. Microstructure Evolution and Wear Behavior of the Laser Cladded CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb High-Entropy Alloy Coatings. J Therm Spray Tech 25, 806–814 (2016). https://doi.org/10.1007/s11666-016-0397-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0397-5