Abstract

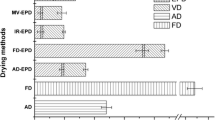

Jackfruit chips are very popular in South Asia; however, the quality of traditional hot air-dried jackfruit chips is not desirable due to brown color and high hardness. The effects of three drying methods, instant controlled pressure drop-assisted freeze drying (FD-DIC), instant controlled pressure drop-assisted hot air drying (AD-DIC), and freeze drying (FD), on the physicochemical characteristics, color, antioxidant activity, expansion ratio, texture, rehydration, hygroscopicity, and microstructure of jackfruit (Artocarpus heterophyllus L.) chips were investigated. The FD-DIC-dried jackfruit chips showed the highest expansion ratio (119 %), the best color (△E, 6.5) and texture (hardness 42 N, crispness 19) compared with the FD- and AD-DIC-dried samples. A substantial increase in pore size was observed in the microstructure of the FD-DIC-dried chips. Compared with AD-DIC, the FD-DIC-finished jackfruit chips exhibited stronger antioxidant capacities (DPPH· free radical scavenging activity, ferric reducing power, and ABTS·+ radical cation scavenging activity) and higher retention of phenolics (1.2 mg GAE g−1) and carotenoids (3.1 μg CE g−1). In conclusion, the jackfruit chips produced by FD-DIC obtained a superior overall quality than the AD-DIC- and FD-dried samples. Considering the relatively high production cost of FD, this novel combination (FD-DIC) could be an alternative method for obtaining high-quality fruit chips or processing valuable agro-products.

Similar content being viewed by others

Abbreviations

- ΔE :

-

Total color difference

- ABTS:

-

2,2-azino-bis (3-ethylbenz-thiazoline-6-suflfonic acid)

- AD:

-

Hot air-drying

- AD-DIC:

-

Instant controlled pressure drop-assisted hot air-drying

- CE:

-

β-carotene equivalents (μg g−1)

- db:

-

Dry basis moisture content (g 100 g−1)

- DPPH:

-

1,1-diphenyl-2-picryl-hydrazyl

- ER:

-

Expansion ratio

- FD:

-

Freeze drying

- FD-DIC:

-

Instant controlled pressure drop-assisted freeze drying

- FRAP:

-

Ferric reducing/antioxidant power

- GAE:

-

Gallic acid equivalents (mg g−1)

- RS:

-

Reducing sugar content (g 100 g−1)

- RR:

-

Rehydration ratio

- TA:

-

Titritable acidity (%)

- TC:

-

Total carotenoid content (μg g−1)

- TE:

-

Trolox equivalent antioxidant capacity (mM g−1)

- TP:

-

Total phenolic content (mg g−1)

- TPTZ:

-

2,4,6-tripyridyl-s-triazine

- TSS:

-

Total soluble solid (°Brix)

- wb:

-

Wet basis moisture content (g 100 g−1)

References

Allaf, T., & Allaf, K. (2014). Instant controlled pressure drop (D.I.C.) in food processing. New York: Springer.

Alonzo-Macias, M., Montejano-Gaitan, G., & Allaf, K. (2014). Impact of drying processes on strawberry (Fragaria var. Camarosa) texture: identification of crispy and crunchy features by instrumental measurement. Journal of Texture Studies, 45(3), 246–259.

Benzie, I. F. (2000). Evolution of antioxidant defence mechanisms. European Journal of Nutrition, 39(2), 53–61.

Benzie, I. F., & Strain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Analytical Biochemistry, 239(1), 70–76.

Bi, J., Wang, X., Chen, Q., Liu, X., Wu, X., Wang, Q., Lv, J., & Yang, A. (2015a). Evaluation indicators of explosion puffing Fuji apple chips quality from different Chinese origins. LWT-Food Science and Technology, 60(2), 1129–1135.

Bi, J., Yang, A., Liu, X., Wu, X., Chen, Q., Wang, Q., Lv, J., & Wang, X. (2015b). Effects of pretreatments on explosion puffing drying kinetics of apple chips. LWT-Food Science and Technology, 60(2), 1136–1142.

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135–148.

Cayuela, J. A. (2008). Vis/NIR soluble solids prediction in intact oranges (Citrus sinensis L.) cv. Valencia Late by reflectance. Postharvest Biology and Technology, 47(1), 75–80.

Chowdhury, M., Bala, B. K., & Haque, M. A. (2011). Energy and exergy analysis of the solar drying of jackfruit leather. Biosystems Engineering, 110(2), 222–229.

Cui, Z., Xu, S., & Sun, D. (2004). Effect of microwave-vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Drying Technology, 22(3), 563–575.

Cui, Z., Li, C., Song, C., & Song, Y. (2008). Combined microwave-vacuum and freeze drying of carrot and apple chips. Drying Technology, 26(12), 1517–1523.

Dias, M. G., Camões, M. F. G. F., & Oliveira, L. (2014). Carotenoid stability in fruits, vegetables, and working standards—effect of storage temperature and time. Food Chemistry, 156(1), 37–41.

Dudonne, S., Vitrac, X., Coutiere, P., Woillez, M., & Mérillon, J. (2009). Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD, and ORAC assays. Journal of Agricultural and Food Chemistry, 57(5), 1768–1774.

Fernandes, F. A., Rodrigues, S., Law, C. L., & Mujumdar, A. S. (2011). Drying of exotic tropical fruits: a comprehensive review. Food and Bioprocess Technology, 4(2), 163–185.

Geidobler, R., & Winter, G. (2013). Controlled ice nucleation in the field of freeze-drying: fundamentals and technology review. European Journal of Pharmaceutics and Biopharmaceutics, 85(2), 214–222.

Giovanelli, G., Zanoni, B., Lavelli, V., & Nani, R. (2002). Water sorption, drying, and antioxidant properties of dried tomato products. Journal of Food Engineering, 52(2), 135–141.

Giraldo-Zuñiga, A. D., Arévalo-Pinedo, A., Rodrigues, R. M., Lima, C., & Feitosa, A. C. (2006). Kinetic drying experimental data and mathematical model for jackfruit (Artocarpus integrifolia) slices. Ciencia y Tecnologia Alimentaria, 5(2), 89–92.

He, X., Liu, J., Cheng, L., & Wang, B. (2013). Quality properties of crispy winter jujube dried by explosion puffing drying. International Journal of Food Engineering, 9(1), 99–106.

Hsu, C., Chen, W., Weng, Y., & Tseng, C. (2003). Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chemistry, 83(1), 85–92.

Hu, Q., Zhang, M., Mujumdar, A. S., Xiao, G., & Jin-cai, S. (2006). Drying of edamames by hot air and vacuum microwave combination. Journal of Food Engineering, 77(4), 977–982.

Huang, L., Zhang, M., Wang, L., Mujumdar, A. S., & Sun, D. (2012). Influence of combination drying methods on composition, texture, aroma, and microstructure of apple slices. LWT-Food Science and Technology, 47(1), 183–188.

Jagadeesh, S. L., Reddy, B. S., Swamy, G. S. K., Gorbal, K., Hegde, L., & Raghavan, G. S. V. (2007). Chemical composition of jackfruit (Artocarpus heterophyllus Lam.) selections of Western Ghats of India. Food Chemistry, 102(1), 361–365.

Jagtap, U. B., Panaskar, S. N., & Bapat, V. A. (2010). Evaluation of antioxidant capacity and phenol content in jackfruit (Artocarpus heterophyllus Lam.) fruit pulp. Plant Foods for Human Nutrition, 65(2), 99–104.

Kozempel, M. F., Sullivan, J. F., Craig, J. C., & Konstance, R. P. (1989). Explosion puffing of fruits and vegetables. Journal of Food Science, 54(3), 772–773.

Krokida, M. K., & Maroulis, Z. B. (1997). Effect of drying method on shrinkage and porosity. Drying Technology, 15(10), 2441–2458.

Krokida, M. K., Karathanos, V. T., & Maroulis, Z. B. (1998). Effect of freeze-drying conditions on shrinkage and porosity of dehydrated agricultural products. Journal of Food Engineering, 35(4), 369–380.

Krokida, M. K., Maroulis, Z. B., & Saravacos, G. D. (2001). The effect of the method of drying on the colour of dehydrated products. International Journal of Food Science and Technology, 36(1), 53–59.

Kumar, C., Karim, M. A., & Joardder, M. U. (2014). Intermittent drying of food products: a critical review. Journal of Food Engineering, 121, 48–57.

Kwok, B., Hu, C., Durance, T., & Kitts, D. D. (2004). Dehydration techniques affect phytochemical contents and free radical scavenging activities of Saskatoon berries (Amelanchier alnifolia Nutt.). Journal of Food Science, 69(3), 122–126.

Lewicki, P. P. (1998). Effect of pre-drying treatment, drying, and rehydration on plant tissue properties: a review. International Journal of Food Properties, 1(1), 1–22.

López, J., Uribe, E., Vega-Gálvez, A., Miranda, M., Vergara, J., Gonzalez, E., & Di Scala, K. (2010). Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning, and firmness of blueberries variety O Neil. Food and Bioprocess Technology, 3(5), 772–777.

Maity, T., Bawa, A.S., & Raju, P.S. (2014). Effect of vacuum frying on changes in quality attributes of jackfruit (Artocarpus heterophyllus) bulb slices. International Journal of Food Science, 2014. doi:10.1155/2014/752047

Maskan, M. (2001). Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. Journal of Food Engineering, 48(2), 177–182.

McCord, J. M. (2000). The evolution of free radicals and oxidative stress. The American Journal of Medicine, 108(8), 652–659.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Moreira, R., Figueiredo, A., & Sereno, A. (2000). Shrinkage of apple disks during drying by warm air convection and freeze drying. Drying Technology, 18(1–2), 279–294.

Mounir, S., Allaf, T., Mujumdar, A. S., & Allaf, K. (2012). Swell drying: coupling instant controlled pressure drop DIC to standard convection drying processes to intensify transfer phenomena and improve quality—an overview. Drying Technology, 30(14), 1508–1531.

Prasantha, B. R., & Amunogoda, P. (2013). Moisture adsorption characteristics of solar-dehydrated mango and jackfruit. Food and Bioprocess Technology, 6(7), 1720–1728.

Pua, C. K., Hamid, N. S. A., Tan, C. P., Mirhosseini, H., Rahman, R. B. A., & Rusul, G. (2010). Optimization of drum drying processing parameters for production of jackfruit (Artocarpus heterophyllus) powder using response surface methodology. LWT-Food Science and Technology, 43(2), 343–349.

Rahman, M. S. (2001). Toward prediction of porosity in foods during drying: a brief review. Drying Technology, 19(1), 1–13.

Ratti, C. (2001). Hot air and freeze-drying of high-value foods: a review. Journal of Food Engineering, 49(4), 311–319.

Saxena, A., Bawa, A. S., & Raju, P. S. (2009). Phytochemical changes in fresh-cut jackfruit (Artocarpus heterophyllus L.) bulbs during modified atmosphere storage. Food Chemistry, 115(4), 1443–1449.

Saxena, A., Bawa, A. S., & Raju, P. S. (2012a). Effect of minimal processing on quality of jackfruit (Artocarpus heterophyllus L.) bulbs using response surface methodology. Food and Bioprocess Technology, 5(1), 348–358.

Saxena, A., Maity, T., Raju, P. S., & Bawa, A. S. (2012b). Degradation kinetics of colour and total carotenoids in jackfruit (Artocarpus heterophyllus) bulb slices during hot air drying. Food and Bioprocess Technology, 5(2), 672–679.

Saxena, A., Saxena, T. M., Raju, P. S., & Bawa, A. S. (2013). Effect of controlled atmosphere storage and chitosan coating on quality of fresh-cut jackfruit bulbs. Food and Bioprocess Technology, 6(8), 2182–2189.

Sidhu, A. S. (2012). Jackfruit improvement in the Asia-Pacific region—a status report. Bangkok, Thailand: Asia-Pacific Association of Agricultural Research Institutions.

Swami, S. B., Thakor, N. J., Haldankar, P. M., & Kalse, S. B. (2012). Jackfruit and its many functional components as related to human health: a review. Comprehensive Reviews in Food Science and Food Safety, 11(6), 565–576.

Taib, M. R., Muhamad, I. I., Ngo, C. L., & Ng, P. S. (2013). Drying kinetics, rehydration characteristics and sensory evaluation of microwave vacuum and convective hot air dehydrated jackfruit bulbs. Jurnal Teknologi, 65(1).

You, Q., Wang, B., Chen, F., Huang, Z., Wang, X., & Luo, P. G. (2011). Comparison of anthocyanins and phenolics in organically and conventionally grown blueberries in selected cultivars. Food Chemistry, 125(1), 201–208.

Zhao, X., Yang, Z., Gai, G., & Yang, Y. (2009). Effect of superfine grinding on properties of ginger powder. Journal of Food Engineering, 91(2), 217–222.

Zou, K., Teng, J., Huang, L., Dai, X., & Wei, B. (2013). Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT-Food Science and Technology, 51(1), 253–259.

Acknowledgments

The authors would like to acknowledge the Special Fund for Agro-scientific Research in the Public Interest Program (No. 201303077) of the Chinese Ministry of Agriculture (MOA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, J., Wang, P., Bi, J. et al. Developing Novel Combination Drying Method for Jackfruit Bulb Chips: Instant Controlled Pressure Drop (DIC)-Assisted Freeze Drying. Food Bioprocess Technol 9, 452–462 (2016). https://doi.org/10.1007/s11947-015-1643-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1643-4