Abstract

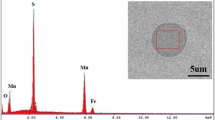

This article reports the morphology, size, and distribution evolution of MnS inclusions in non-quenched and tempered steel during heat treatment. The variation of single large-sized MnS inclusions at high temperature was observed in situ using a confocal scanning laser microscope (CSLM). The slender MnS inclusions first changed to pearl-like strings. These small-sized pearls subsequently coalesced and became closer together as the temperature increased. Large-sized MnS inclusions in non-quenched and tempered steel samples with different thermal histories were investigated with respect to the evolution of their morphology, size, and distribution. After 30 min of ovulation at 1573 K, the percentage of MnS inclusions larger than 3 µm decreased from 50.5% to 3.0%. After a 3 h soaking period, Ostwald ripening occurred. Most MnS inclusions moved from the grain boundaries to the interior. The present study demonstrates that heat treatment is an effective method of changing the morphology, size, and distribution of MnS inclusions, especially large-sized ones.

Similar content being viewed by others

References

J.S. Byun, J.H. Shim, Y.C. Cho, and D.N. Lee, Non-metallic inclusion and intragranular nucleation of ferrite in Ti-killed C–Mn steel, Acta Mater., 51(2003), No. 6, p. 1593.

Z.Z. Liu, Y. Kobayashi, F.X. Yin, M. Kuwabara, and K. Nagai, Nucleation of acicular ferrite on sulfide inclusion during rapid solidification of low carbon steel, ISIJ Int., 47(2007), No. 12, p. 1781.

T. Furuhara, T. Shinyoshi, G. Miyamoto, J. Yamaguchi, N. Sugita, N. Kimura, N. Takemura, and T. Maki, Multiphase crystallography in the nucleation of intragranular ferrite on MnS+V(C,N) complex precipitate in austenite, ISIJ Int., 43(2003), No. 12, p. 2028.

J.W. Flowers Jr. and S.P. Karas, Coalescence of sulfides during secondary growth in 3% silicon–iron, J. Appl. phys., 38(1967), No. 3, p. 1085.

D. Gnanamuthu, T.Z. Kattamis, M.C. Flemings, and R. Mehrabian, Effect of homogenization on sulfide inclusions in ferrous alloys, Metall. Trans., 5(1974), No. 12, p. 2557.

W.H. McFarland and J.T. Cronn, Spheroidization of type II manganese sulfides by heat treatment, Metall. Trans. A, 12(1981), No. 5, p. 916.

Y.V. Murty, J.E. Morral, T.Z. Kattamis, and R. Mehrabian, Initial coarsening of manganese sulfide inclusions in rolled steel during homogenization, Metall. Trans. A, 6(1975), No. 11, p. 2031.

Y.V. Murty, T.Z. Kattamis, R. Mehrabian, and M.C. Flemings, Behavior of sulfide inclusions during thermomechanical processing of AISI 4340 steel, Metall. Trans. A, 8(1977), No. 8, p. 1275.

P.C. Wilson, Y.V. Murty, T.Z. Kattamis, and R. Mehrabian, Effect of homogenization on sulphide morphology and mechanical properties of rolled AISI 4340 steel, Met. Technol., 2(1975), No. 1, p. 241.

M. Nishida, T. Kato, and T. Tanaka, Spheroidization of manganese sulfide inclusion during heating and its effect on hydrogen induced cracking in rolled steel, Tetsu-to-Hagane, 67(1981), No. 9, p. 1533.

X.J. Shao, X.H. Wang, M. Jiang, W.J. Wang, and F.X. Huang, Effect of heat treatment conditions on shape control of large-sized elongated MnS inclusions in resulfurized free-cutting steels, ISIJ Int., 51(2011), No. 12, p. 1995.

X.J. Shao, X.H. Wang, M. Jiang, W.J. Wang, F.X. Huang, and Y.Q. Ji, In situ observation of MnS inclusion behavior in resulfurized free-cutting steel during heating, Acta Metall. Sin., 47(2011), No. 9, p. 1210.

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki, “In-situ” observation of collision, agglomeration and cluster formation of alumina inclusion particles on steel melts, ISIJ Int, 37(1997), No. 10, p. 936.

H. Hasegawa, K. Nakajima, and S. Mizoguchi, The effects of inclusions in steel on MnS precipitation in Fe-Si alloys, Tetsu-to-Hagane, 87(2001), No. 11, p. 700.

C.E. Sims and F.B. Dahle, Effect of aluminum on the properties of medium carbon cast steel, Trans. AFS, 46(1938), p. 65.

F.A. Nichols and W.W. Mullins, Surface-(interface-) and volume-diffusion contributions to morphological changes driven by capillarity, Trans. AIME, 233(1965), p. 1840.

F.A. Nichols, On the spheroidization of rod-shaped particles of finite length, J. Mater. Sci., 11(1976), No. 6, p. 1077.

D.B. Rayaprolu and D. Jaffrey, Kinetics of Ostwald ripening: an analysis of models and errors with reference to MnS inclusions in steel, Mater. Charact., 24(1990), No. 3, p. 245.

M. Suzuki, C.H. Yu, H. Shibata, and T. Emi, Recovery of hot ductility by improving thermal pattern of continuously cast low-carbon and ultra-low-carbon steel slabs for hot direct rolling, ISIJ Int., 37(1997), No. 9, p. 862.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, Xj., Wang, Xh., Ji, Cx. et al. Morphology, size and distribution of MnS inclusions in non-quenched and tempered steel during heat treatment. Int J Miner Metall Mater 22, 483–491 (2015). https://doi.org/10.1007/s12613-015-1097-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1097-8