Abstract

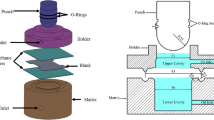

A new approach is presented in this paper to calculate the critical threshold value of fracture initiation. It is based on the experimental data for forming limit curves and fracture forming limit curves. The deformation path for finally a fractured material point is assumed as two-stage proportional loading: biaxial loading from the beginning to the onset of incipient necking, followed plane strain deformation within the incipient neck until the final fracture. The fracture threshold value is determined by analytical integration and validated by numerical simulation. Four phenomenological models for ductile fracture are selected in this study, i.e., Brozzo, McClintock, Rice-Tracey, and Oyane models. The threshold value for each model is obtained through best-fitting of experimental data. The results are compared with each other and test data. These fracture criteria are implemented in ABAQUS/EXPLICIT through user subroutine VUMAT to simulate the blanking process of advanced high-strength steels. The simulated fracture surfaces are examined to determine the initiation of ductile fracture during the process, and compared with experimental results for DP780 sheet steel blanking. The comparisons between FE simulated results coupled with different fracture models and experimental one show good agreements on punching edge quality. The study demonstrates that the proposed approach to calculate threshold values of fracture models is efficient and reliable. The results also suggest that the McClintock and Oyane fracture models are more accurate than the Rice-Tracey or Brozzo models in predicting load-stroke curves. However, the predicted blanking edge quality does not have appreciable differences.

Similar content being viewed by others

References

A. Nasser, A. Yadav, P. Pathak, and T. Altan, Determination of the Flow Stress of Five AHSS Sheet Materials (DP 600, DP 780, DP 780-CR, DP 780-HY and TRIP 780) Using the Uniaxial Tensile and the Biaxial Viscous Pressure Bulge (VPB) Tests, J. Mater. Process. Technol., 2010, 210, p 429–436

K. Chung, N. Ma, T. Park, D. Kim, D. Yoo, and C. Kim, A Modified Damage Model for Advanced High Strength Steel Sheets, Int. J. Plast., 2011, 27, p 1485–1511

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. Lond. A, 1948, 193, p 281–297

H. Li, M.-W. Fu, J. Lu, and H. Yang, Ductile Fracture—Experiments and Computations, Int. J. Plast., 2011, 27, p 147–180

N. Hatanaka, K. Yamaguchi, and N. Takakura, Finite Element Simulation of the Shearing Mechanism in the Blanking of Sheet Metal, J. Mater. Process. Technol., 2003, 139, p 64–70

A.-L. Gurson, Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I, Yield Criteria and Flow Rules for Porous Ductile Media, J. Eng. Mater. Technol., 1977, 99, p 2–15

V. Tvergaard, Influence of Voids on Shear Band Instabilities under Plane Strain Conditions, Int. J. Fract., 1981, 17, p 389–407

V. Tvergaard, On Localization in Ductile Materials Containing Spherical Voids, Int. J. Fract., 1982, 18, p 237–252

A. Needleman and V. Tvergaard, An Analysis of Ductile Rupture in Notched Bars, J. Mech. Phys. Solids, 1984, 32, p 2–15

K. Nahshon and J.-W. Hutchinson, Modification of the Gurson Model for Shear Failure, Eur. J. Mech. A, 2008, 27, p 1–17

F.-A. McClintock, A Criterion for Ductile Fracture by the Growth of Holes Subjected to Multi-axial Stress States, J. Appl. Mech., 1968, 35, p 363–371

M. Oyane, Criteria of Ductile Fracture Strain, Bull. JSME, 1972, 15, p 1507–1513

P. Brozzo, B. Deluca, R. Rendina, A New Method for the Prediction of Formability Limits in Metal Sheets, Sheet Metal Forming and Formability, Proceedings of the 7th Biennial Conference of the International Deep Drawing Research Group (Amsterdam, The Netherlands), 1972, p 9–13

J.-R. Rice and D.-M. Tracey, On the Ductile Enlargement of Voids in Triaxial Stress Fields, J. Mech. Phys. Solids, 1969, 17, p 201–217

T. Wierzbicki, Y.-B. Bao, Y.-W. Lee, and Y.-L. Bai, Calibration and Evaluation of Seven Fracture Models, Int. J. Mech. Sci., 2005, 47, p 719–743

A.-M. Goijaerts, L.-E. Govaert, and F.-P.-T. Baaijens, Evaluation of Ductile Fracture Models for Different Metals in Blanking, J. Mater. Process. Technol., 2001, 110, p 312–323

G. Huang, B. Yan, H. Zhu, Measurement of Fracture Strains for AHSS Using Digital Image Correlation, SAE 2009 World Congress (Detroit, USA), 2009-01-1174

M. Jain and J. Allin, Effect of Reverse Dome Stretching on Dome Height and Forming Limits of Sheet Materials, Mater. Sci. Eng., 2005, A390, p 210–216

D. Lecompte, Quality Assessment of Speckle Patterns for Digital Image Correlation, Opt. Lasers Eng., 2006, 44, p 1132–1145

B. Pan and K. Li, A Fast Digital Image Correlation Method for Deformation Measurement, Opt. Lasers Eng., 2011, 49, p 841–847

H. Hencky, Zur theorie plastischer deformationen und der hierdurch im material hervorgerufenen nachspannungen, Proceedings of the International Congress for Applied Mechanics (Delft, The Netherlands), 1924, p 22–26

Hibbitt, Karlsson & Sorensen, Inc., ABAQUS/Theory Manual, 2008, Version 6.8

Hibbitt, Karlsson & Sorensen, Inc., ABAQUS/User Subroutines Reference Manual, 2008, Version 6.8

M.-L. Wilkins, Methods of Computational Physics, Vol 3, B. Adler, S. Ferbach, and M. Rotenberg, Ed., Academic Press, New York, 1964, p 211–263

Acknowledgments

The research work is funded by Ford Motor Company through its University Research Program (URP), and co-funded by National Natural Science Foundation of China through Grant 51105246 and National Key Specific Science & Technology Program from Ministry of Industry and Information Technology of China through Grant 2010ZX04014-072. The authors are grateful to Dr. Gang Huang of Arcelor Mittal Research & Development for making available the test data used in this paper, and also for the helpful discussions with him.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Chen, J., Xia, C. et al. A New Method to Calculate Threshold Values of Ductile Fracture Criteria for Advanced High-Strength Sheet Blanking. J. of Materi Eng and Perform 23, 1296–1306 (2014). https://doi.org/10.1007/s11665-013-0861-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0861-z