Abstract

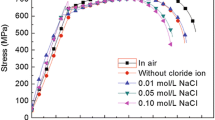

In this work, the anodic dissolution behavior of the fresh metal surface at crack tip of X70 steel in near-neutral pH environment was investigated using galvanic corrosion simulation method. The solution environment, strain, strain rate, hydrogen enrichment, and fresh metal surface at the crack tip were considered. Corrosion current of the specimen during fast stretching increased linearly with plastic strain. The increment and increase rate of the corrosion current during plastic deformation stage were dependent on the strain rate. Combining Faraday’s law and crack tip strain rate equation, the crack growth rate (CGR) induced by the anodic dissolution of the fresh metal surface was calculated. Results show that CGR caused by anodic dissolution was roughly one order lower than that measured on the compact tensile specimen under cyclic load. This finding indicated that hydrogen embrittlement may play a dominate role in stress corrosion crack propagation of pipeline steels in near-neutral pH environment.

Similar content being viewed by others

References

R.N. Parkins, W. Blanchard, Jr., and B. Delanty, Transgranular Stress Corrosion Cracking of High-Pressure Pipelines in Contact with Solutions of Near Neutral pH, Corrosion, 1994, 50, p 394–408

J.A. Beavers, 2013 Frank Newman Speller Award Lecture: Integrity Management of Natural Gas and Petroleum Pipelines Subject to Stress Corrosion Cracking, Corrosion, 2013, 70, p 3–18

X. Tang and Y.F. Cheng, Quantitative Characterization by Micro-Electrochemical Measurements of the Synergism of Hydrogen, Stress and Dissolution on Near-Neutral pH Stress Corrosion Cracking of Pipelines, Corros. Sci., 2011, 53, p 2927–2933

Y. Huang, F.Z. Xuan, S.T. Tu, and T. Itoh, Effects of Hydrogen and Surface Dislocation on Active Dissolution of Deformed 304 Austenitic Stainless Steel in Acid Chloride Solution, Mater. Sci. Eng. A, 2011, 528, p 1882–1888

Z.Y. Cui, Z.Y. Liu, X.Z. Wang, Q. Li, C.W. Du, and X.G. Li, Crack Growth Behavior and Crack Tip Chemistry of X70 Pipeline Steel in Near-Neutral pH Environment, Corros. Eng. Sci. Technol., 2016, 51, p 352–357

R.N. Parkins, Current Topics in Corrosion: Factors Influencing Stress Corrosion Crack Growth Kinetics, Corrosion, 1987, 43, p 130–139

L.J. Qiao, J.L. Luo, and X.J. Mao, Hydrogen Evolution and Enrichment Around Stress Corrosion Crack Tips of Pipeline Steels in Dilute Bicarbonate Solution, Corrosion, 1998, 54, p 115–120

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Effect of Strain Rate on Cathodic Reaction During Stress Corrosion Cracking of X70 Pipeline Steel in a Near-Neutral pH Solution, J. Mater. Eng. Perform., 2011, 20, p 1242–1246

R.N. Parkins, Predictive Approaches to Stress Corrosion Cracking Failure, Corros. Sci., 1980, 20, p 147–166

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Mechanistic Aspect of Near-Neutral pH Stress Corrosion Cracking of Pipelines Under Cathodic Polarization, Corros. Sci., 2012, 55, p 54–60

T.R. Beck, Electrochemical Techniques for Corrosion: Symposium on Electrochemical Techniques for Corrosion at the NACE Corrosion/76 meeting held in Houston, Texas, March 22–26, 1976, NACE1977

A. Alavi, C.D. Miller, and R.P. Wei, A Technique for Measuring Kinetics of Electrochemical Reactions with Bare Metal Surfaces, Corrosion, 1987, 43, p 204–207

R.P. Wei, M. Gao, and P.Y. Xu, Peak Bare Surface Current Densities Overestimated in Straining and Scratching Electrode Experiments, J. Electrochem. Soc., 1989, 136, p 1835–1836

T.P. Hoar and J.R. Galvele, Anodic Behaviour of Mild Steel During Yielding in Nitrate Solutions, Corros. Sci., 1970, 10, p 211–224

R.C. Newman and K. Sieradzki, Electrochemical Aspects of Stress-Corrosion Cracking of Sensitised Stainless Steels, Corros. Sci., 1983, 23, p 363–378

W. Zhao, R. Xin, Z. He, and Y. Wang, Contribution of Anodic Dissolution to the Corrosion Fatigue Crack Propagation of X80 Steel in 3.5 wt.% NaCl Solution, Corros. Sci., 2012, 63, p 387–392

GB-T15970, Chinese National Standard for Stress Corrosion Cracking Tests, 2007.

J. Capelle, I. Dmytrakh, and G. Pluvinage, Comparative Assessment of Electrochemical Hydrogen Absorption by Pipeline Steels with Different Strength, Corros. Sci., 2010, 52, p 1554–1559

Z.Y. Cui, Z.Y. Liu, L.W. Wang, C.W. Du, and X.G. Li, Effect of pH Value on the Crack Growth Behavior of X70 Pipeline Steel in the Dilute Bicarbonate Solutions, Mater. Trans., 2015, 56, p 777–780

ASTM E647, Standard test method for fatigue crack growth rates, The American Society for Testing of Materials, 2005.

M. Zhu, G. Ou, H. Jin, C. Du, X. Li, and Z. Liu, Study on the Crack Propagation Behavior of X80 Pipeline Steel Under AC Application in High pH Solution, J. Mater. Eng. Perform., 2015, 24, p 2422–2425

E.M. Gutman, Mechanochemistry of Materials, Cambridge Int Science Publishing, Cambridge, 1998

L.Y. Xu and Y.F. Cheng, Corrosion of X100 Pipeline Steel Under Plastic Strain in a Neutral pH Bicarbonate Solution, Corros. Sci., 2012, 64, p 145–152

A.R. Despic, R.G. Raicheff, and J.O.M. Bockris, Mechanism of the Acceleration of the Electrodic Dissolution of Metals During Yielding Under Stress, J. Chem. Phy., 1968, 49, p 926–938

W. Li, M. Cai, Y. Wang, and S. Yu, Influences of Tensile Strain and Strain Rate on the Electron Work Function of Metals and Alloys, Scripta Mater., 2006, 54, p 921–924

Z.Y. Cui, Z.Y. Liu, L.W. Wang, H.C. Ma, C.W. Du, X.G. Li, and X. Wang, Effect of pH Value on the Electrochemical and Stress Corrosion Cracking Behavior of X70 Pipeline Steel in the Dilute Bicarbonate Solutions, J. Mater. Eng. Perform., 2015, 24, p 4400–4408

B.T. Lu, Crack Growth Model for Pipeline Steels Exposed to Near-Neutral pH Groundwater, Fatigue Fract. Eng. Mater. Struct., 2013, 36, p 660–669

W. Chen and R.L. Sutherby, Crack Growth Behavior of Pipeline Steel in Near-Neutral pH Soil Environments, Metall. Mater. Trans. A, 2007, 38, p 1260–1268

F.M. Song, Predicting the Mechanisms and Crack Growth Rates of Pipelines Undergoing Stress Corrosion Cracking at High pH, Corros. Sci., 2009, 51, p 2657–2674

T. Shoji, Z. Lu, and H. Murakami, Formulating Stress Corrosion Cracking Growth Rates by Combination of Crack Tip Mechanics and Crack Tip Oxidation Kinetics, Corros. Sci., 2010, 52, p 769–779

Q.J. Peng, J. Kwon, and T. Shoji, Development of a Fundamental Crack Tip Strain Rate Equation and Its Application to Quantitative Prediction of Stress Corrosion Cracking of Stainless Steels in High Temperature Oxygenated Water, J. Nucl. Mater., 2004, 324, p 52–61

B.T. Lu, F. Song, M. Gao, and M. Elboujdaini, Crack Growth Model for Pipelines Exposed to Concentrated Carbonate–Bicarbonate Solution with High pH, Corros. Sci., 2010, 52, p 4064–4072

B.T. Lu, Further Study on Crack Growth Model of Buried Pipelines Exposed to Concentrated Carbonate–Bicarbonate Solution, Eng. Fract. Mech., 2014, 131, p 296–314

S.F. Bubar and D.A. Vermilyea, Deformation of Anodic Oxide Films, J. Electrochem. Soc., 1966, 113, p 892–895

Acknowledgments

The authors wish to acknowledgement the financial support of National Natural Science Foundation of China (Nos. 51471034, 51131001 and 51601182) and National Basic Research Program of China (973 Program Project, No. 2014CB643300).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Z., Wang, L., Liu, Z. et al. Anodic Dissolution Behavior of the Crack Tip of X70 Pipeline Steel in Near-Neutral pH Environment. J. of Materi Eng and Perform 25, 5468–5476 (2016). https://doi.org/10.1007/s11665-016-2394-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2394-8