Abstract

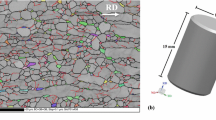

The conventional Arrhenius-type model was adopted to identify the deformation characteristic of Ti6Al4V (TC4) titanium alloy based on the stress–strain curves of isothermal compression test. A new flow stress model based on Arrhenius equation was proposed for TC4, which is composed of peak flow stress (PFS) prediction and strain compensation. The predicted PFS is set as a reference to derive the flow stress model at any strain ranging from approximately 0 to 0.7. The predictability and efficiency among the proposed model, conventional model, and an existing physical-based model of TC4 were comparatively evaluated. It is found that the newly proposed model can simultaneously track the hardening and softening behaviors of TC4 through a single expression while the other existing models are only valid in the softening region. Besides, the wider application range and acceptable accuracy of the new model have been achieved by fewer material constants with much-simplified modeling procedure than the other models.

Similar content being viewed by others

References

Haghdadi N, Martin D, Hodgson P. Physically-based constitutive modelling of hot deformation behavior in a LDX 2101 duplex stainless steel. Mater Des. 2016;106:420.

Lin YC, Chen XM. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des. 2011;32(4):1733.

Li MQ, Xiong AM, Wang HR, Su SB, Shen LC. Deformation behaviour and new constitutive equation utilising the grain size of commercial TC6 titanium alloy. Mater Sci Technol. 2004;20(10):1261.

Luo J, Ye P, Li MQ, Liu LY. Effect of the alpha grain size on the deformation behavior during isothermal compression of Ti–6Al–4V alloy. Mater Des. 2015;88:32.

Lurdos O, Montheillet F, Damamme G. Empirical and physically based flow rules relevant to high speed processing of 304L steel. Int J Mater Form. 2008;1(1):1431.

Luo J, Li M, Li X, Shi Y. Constitutive model for high temperature deformation of titanium alloys using internal state variables. Mech Mater. 2010;42(2):157.

Velay V, Matsumoto H, Vidal V, Chiba A. Behavior modeling and microstructural evolutions of Ti-6Al-4V alloy under hot forming conditions. Int J Mech Sci. 2016;108:1.

Rusinek A, Rodríguez-Martínez JA, Arias A. A thermo-viscoplastic constitutive model for FCC metals with application to OFHC copper. Int J Mech Sci. 2010;52(2):120.

Tao ZJ, Yang H, Li H, Ma J, Gao PF. Constitutive modeling of compression behavior of TC4 tube based on modified Arrhenius and artificial neural network models. Rare Met. 2016;35(2):162.

Haghdadi N, Zarei-Hanzaki A, Khalesian AR, Abedi HR. Artificial neural network modeling to predict the hot deformation behavior of an A356 aluminum alloy. Mater Des. 2013;49:386.

Sellars CM, Mctegart WJ. On the mechanism of hot deformation. Acta Metall. 1966;14(9):1136.

Haghdadi N, Zarei-Hanzaki A, Abedi HR. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain. Mater Sci Eng A. 2012;535:252.

Lin YC, Chen MS, Zhang J. Modeling of flow stress of 42CrMo steel under hot compression. Mater Sci Eng A. 2009;499(1–2):88.

Sun CY, Liu JR, Li R, Zhang QD, Dong JX. Rare Metals Constitutive relationship of IN690 superalloy by using uniaxial compression tests. Rare Met. 2011;30(1):81.

Cai J, Li F, Liu T, Chen B, He M. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain. Mater Des. 2011;32(3):1144.

Samantaray D, Mandal S, Bhaduri AK. A comparative study on Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr–1Mo steel. Comput Mater Sci. 2009;47(2):568.

He A, Wang X, Xie G, Zhang H. A comparative study on Johnson-Cook, modified Johnson-Cook and Arrhenius-type constitutive models to predict the high temperature flow stress in 20CrMo alloy steel. Mater Des. 2013;52(24):677.

Liu J, Zeng W, Zhu Y, Yu H, Zhao Y. Hot deformation behavior and flow stress prediction of TC4-DT alloy in single-phase region and dual-phase regions. J Mater Eng Perform. 2015;24(5):2140.

Mcqueen HJ, Ryan ND. Constitutive analysis in hot working. Mater Sci Eng A. 2002;322(1–2):43.

Zhang C, Ding J, Dong Y, Zhao G, Gao A, Wang L. Identification of friction coefficients and strain-compensated Arrhenius-type constitutive model by a two-stage inverse analysis technique. Int J Mech Sci. 2015;98:195.

Peng X, Guo H, Shi Z, Qin C, Zhao Z. Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature. Mater Des. 2013;50(17):198.

Jia BH, Song WD, Tang HP, Wang ZH, Mao XN, Ning JG. Hot deformation behavior and constitutive model of TC18 alloy during compression. Rare Met. 2014;33(4):383.

Lin YC, Liu G. A new mathematical model for predicting flow stress of typical high-strength alloy steel at elevated high temperature. Comput Mater Sci. 2010;48(1):54.

Liu J, Cui Z, Li C. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B. Comput Mater Sci. 2008;41(3):375.

He X, Yu Z, Lai X. A method to predict flow stress considering dynamic recrystallization during hot deformation. Comput Mater Sci. 2008;44(2):760.

Luo J, Wu B, Li M. 3D finite element simulation of microstructure evolution in blade forging of Ti–6Al–4V alloy based on the internal state variable models. Int J Min Met Mater. 2012;19(2):122.

Zener C, Hollomon JH. Effect of strain rate upon plastic flow of steel. J Appl Phys. 1944;15(1):22.

Luo J, Li M, Li H, Yu W. Effect of the strain on the deformation behavior of isothermally compressed Ti–6Al–4V alloy. Mater Sci Eng A. 2009;505(1–2):88.

Jia W, Zeng W, Zhou Y, Liu J, Wang Q. High-temperature deformation behavior of Ti60 titanium alloy. Mater Sci Eng A. 2011;528(12):4068.

Wanjara P, Jahazi M, Monajati H, Yue S, Immarigeon J-P. Hot working behavior of near-α alloy IMI834. Mater Sci Eng A. 2005;396(1–2):50.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 51475295).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, FH., Xiong, W., Li, XF. et al. A new flow stress model based on Arrhenius equation to track hardening and softening behaviors of Ti6Al4V alloy. Rare Met. 37, 1035–1045 (2018). https://doi.org/10.1007/s12598-017-0979-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0979-5