Abstract

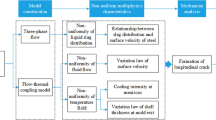

Finite element models of steady heat conduction for cross section of beam blank mold were developed by using ABAQUS software. The effect of mold grinding thickness, cooling water velocity, diameter of restrictor rods and water channel design on hot face temperature was analyzed in detail. Attention was focused on the peak temperature and temperature uniformity along hot face. The results showed that the peak temperature of existing mold, about 337.2 °C, is located in the fillet, and two valleys of hot face temperature are found in flange corner and junction of wide face and narrow face, respectively. Decreasing mold thickness, increasing cooling water velocity and increasing diameter of restrictor rods can all reduce peak temperature and improve temperature uniformity along hot race at the expense of lower overall temperature. Redesigning the water channel can decrease peak temperature and thermal gradient of mold without lowering overall temperature of hot face. In particular, the small hole design can improve temperature uniformity across hot face and obtain the best advantage.

Similar content being viewed by others

References

Park J K, Thomas B G, Indira V Samarasekera, et al. Thermal and Mechanical Behavior of Copper Molds During Thin-Slab Casting (I): Plant Trial and Mathematical Modeling [J]. Metallurgical and materials Transactions B, 2002, 33(3): 425.

Thomas G O’Connor, Jonathan A Dantzig. Modeling the Thin-Slab Continuous-Casting Mold [J]. Metallurgical and Materials Transactions B, 1994, 25(3): 443.

Mahapatra R B, Brimacombe J K, Samarasekera I V, et al. Mold Behavior and Its Influence on Quality in the Continuous Casting of Steel Slabs: Part I: Industrial Trials, Mold Temperature Measurements, and Mathematical Modeling [J]. Metallurgical and Materials Transactions B, 1991, 22(6): 861.

Thomas B G, Langeneckert M, Castella L, et al. Optimisation of Narrow Face Water Slot Design for Siderar Slab Casting Mould [J]. Ironmaking and Steelmaking, 2003, 30(3): 235.

Xudong LIU, Miaoyong ZHU. Finite Element Analysis of Thermal and Mechanical Behavior in a Slab Continuous Casting Mold [J]. ISIJ International, 2006, 46(11): 1652.

Samarasekera I V, Anderson D L, Brimacombe J K. The Thermal Distortion of Continuous-Casting Billet Molds [J]. Metallurgical and Materials Transactions B, 1982, 13(1): 91.

Thomas B G, Jiang J, Lorento D. Optimization of Water Channel Design in Beam-Blank Molds [A]. Proc. 5th European Continuous Casting Conference [C]. Paris: The Institute of Materials, Minerals and Mining, 2005, 139.

HAN Zhi-wei, FENG Ke, WANG Yong, et al. Optimum Design on Cooling Framework of Mold Copper Plate [J]. Foundry Technology, 2007, 28(6): 856.

Park J K, Thomas B G, Indira V Samarasekera, et al. Thermal and Mechanical Behavior of Copper Molds during Thin-Slab Casting (II): Mold Crack Formation [J]. Metallurgical and Materials Transactions B, 2002, 33(3): 437.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Hl., Wen, Gh., Sun, W. et al. Analysis of thermal behavior for beam blank continuous casting mold. J. Iron Steel Res. Int. 17, 17–22 (2010). https://doi.org/10.1016/S1006-706X(10)60191-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60191-4